The Blue Ridge Luthiers

Meeting at Pat Dewar's shop in Wirtz, VA

July 12, 2025

Main Event

Pat explains his week at the Robbie O'Brien 6 Day Guitar Build course

Day 1 - full 8 hours

- Cutting sides to width

- Thickness sides with the safety planer

- Thickness back with the safety planer

- Finish Back/Sides with a drum sander

- Side layout

- Pre-tapering the sides

- Bending a side and bindings

- Making the end block

- Making the heel block

- Sanding and sealing the heel block

- Bending the other side

- Joining the soundboard

- Joining the back

- Scarf joint on the neck

- Slotting the fretboard

- Tapering the fretboard

- Cutting sides to length

- Gluing blocks to the sides

- Roughing out braces

- Lunch

- AFTERNOON

- Radiusing the rims

- Installing kerfing

- Preparing soundboard for the rosette

- Installing the rosette

- Thickness peghead

- Scale layout

- The truss rod slot

- Gluing veneers and blocks

- Final thickness of back

- Back reinforcement

- The end wedge

- Sanding rosette flush

- Thickness the top

- Cutting out the soundhole

- Cutting top to shape

- Scraping end wedge

- Driving the bus

Day 1 - 5 pm

Day 2 - full 8 hours

- Bracing discussion

- Marking bracing pattern on top

- Radiusing braces

- X brace lap joint

- 1st glue stage

- Upper transverse brace and tongue

- depressor

- Bridge patch and other braces

- 2nd glue stage

- Radiusing back braces

- Planing reinforcement strip

- Cutting back to shape

- 3rd glue stage

- Fitting braces to back

- Tapering brace ends

- Gluing back braces

- Voicing discussion

- Voicing

- Fitting top to rims

- Shaping back braces

- Fitting back to rims

- Closing the box

- AFTERNOON

- Flush trimming back and top

- Binding cutter setup

- Cutting binding channels

- Channel cleanup

- Prepping bindings

- Installing top bindings

- Installing back bindings

- Cutting veneers at nut

- The volute

- Peghead shape

- Tuner holes

- Neck prep

- Body prep

- Body mortise cavity

- Neck tenon

- Setting the neck

- Attaching the fretboard

- The heel cap

- END OF DAY 2

Day 2 - 5 pm

Day 3 - less than full day

- Scraping bindings

- Scraping side bindings

- Neck carving step

- Leveling and radiusing the fretboard

- Fret markers

- Side markers

- Prepping for frets

- Installing frets

- Fretwork

- Sanding the neck

- AFTERNOON

- Sanding the body

- Pore filling the neck

- Masking bridge location

- Sealing the soundboard

- First polishing session on top

- First epoxy pore fill

- END OF DAY 3 (3pm)

Day 3 - Working

Day 3 - End of day, 3pm

Day 4 - half day

- Sanding epoxy pore fill

- Leveling the finish

- Second polishing session on top

- Bridge thickness

- Rough bridge shape

- Third polishing session on top

- Slotting and final shaping of bridge

- Spiriting off

- Second epxoy pore fill

- Sanding second epoxy pore fill

- END OF DAY 4 (noon)

Day 5 - half day

- Attaching the bridge

- Sealing the side

- Removing the bridge clamp

- Polishing the sides

- Polishing the neck and back

- Leveling and more polish on sides

- Leveling and more polish on back and neck

- END OF DAY 5 (noon)

Day 6

- Cleaning the fretboard

- Fitting and shaping the nut

- Slotting the nut

- Oiling the fretboard

- Bridge pin holes

- The saddle

- Installing tuners

- The label

- Strings

- Neck relief

- Action at the nut

- Action at the 12th fret

- Intonation

- Test drive

- END OF DAY 6 (11am)

Day 6 - Saturday afternnon flight home

Other stuff

Justin's finishing tests

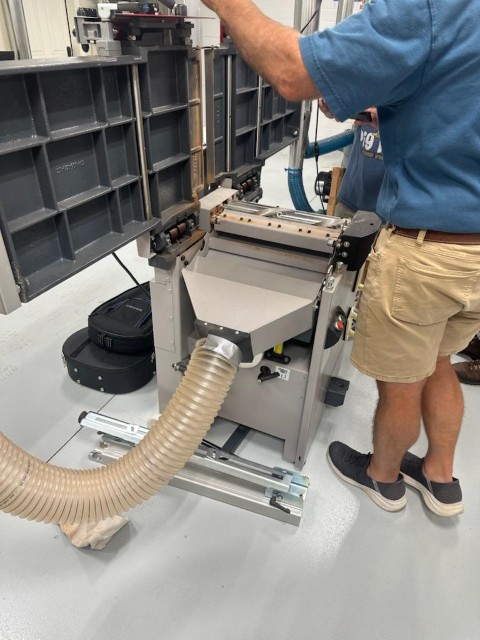

Pat's Jointer/planer

This Hammer A3 41 jointer/planer combo machine will joint and plane pieces 16" wide - great for solid guitar bodies.

In Pat's workshop